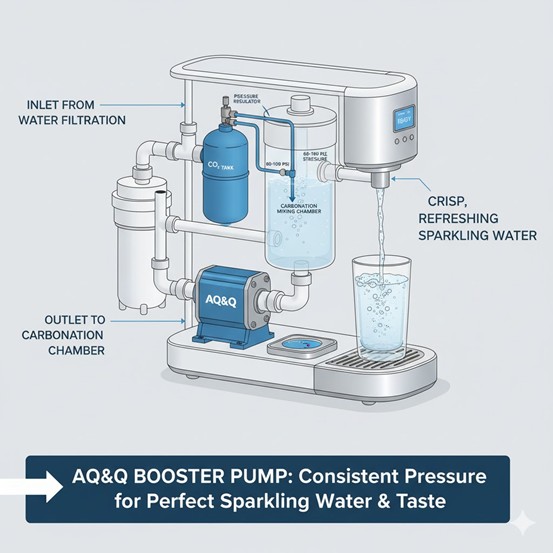

Beverage Pump

In sparkling water machines, AQ&Q booster

pumps are essential for ensuring consistent water pressure during carbonation.

These machines work by injecting CO₂ into water, a process that requires stable

pressure to achieve proper gas dissolution and bubble formation. AQ&Q booster

pumps help maintain the ideal pressure range—typically between 60 to 100

psi—ensuring that the carbonation is uniform and efficient. AQ&Q booster

pumps used in this sector are typically made of food-grade materials such as hygienic proved material and stainless steel to meet sanitary regulations.

In commercial or industrial units, where

multiple servings or high-speed dispensing is required, AQ&Q booster pumps

ensure rapid and consistent performance without pressure drops. They also

improve the mixing process, enhancing taste and fizziness, which is critical

for customer satisfaction. In home or countertop units, compact and low-noise

booster pumps are used to provide a smooth user experience while maintaining

carbonation quality. Additionally, in systems connected to water filtration or

chilling units, AQ&Q booster pumps support steady flow and integration. By

enabling consistent CO₂ infusion, booster pumps are key to delivering crisp,

refreshing sparkling water every time.